Invented in 1988 by our founder Dr. Nathan Cohen, fractal antennas have become globally accepted as the highest performing antenna elements available.

Learn more

We are pioneers in the field of metamaterials. These powerful resonators provide profound benefits applicable to a wide range of end-uses.

Learn more

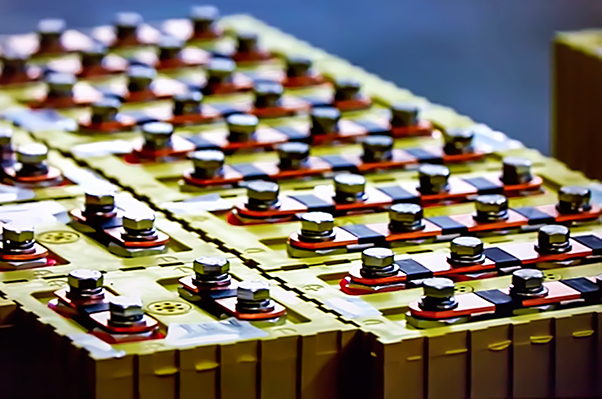

From batteries, to heat exchangers, to circuit design - we have applied the natural power of fractals to a multitude of additional electromagnetic domains.

Learn more

Fractal geometry creates virtual combination of capacitance and inductance, driving multiple resonances across the same element structure.

Fractal geometry’s self-inductance and capacitance allow element to shrink in size versus traditional design

Antennas require less circuitry, with fewer radiative elements to reach desired bandwidth. There are no inductors or capacitors required

Fractal geometry allows for multiple current maxima across smaller element, increasing gain acheived by the element

Wideband resonators absorb electromagnetic radiation and "cloak" object by cancelling back scatter and enhancing front scatter

Wideband fractal metamaterials prevent electromagnetic penetration by absorbing radiation and diverting it through evanescent surface wave effect

Wideband fractal resonators increase absorptive passband and capacity by distributing energy through evanescent wave effect

Efficient wideband electromagetic energy transfer through the distribution of evanescent surface waves across a surface or area

Fractal's IP supports the "fractalization" of battery electrodes to increase power density and reduce dendrite formation.

The fractalization technique can be applied to any electrode material (e.g., C, Si, MgX, etc.). Higher density means more time between charges, and fewer dendrites mean safer, longer-lasting battery technology.

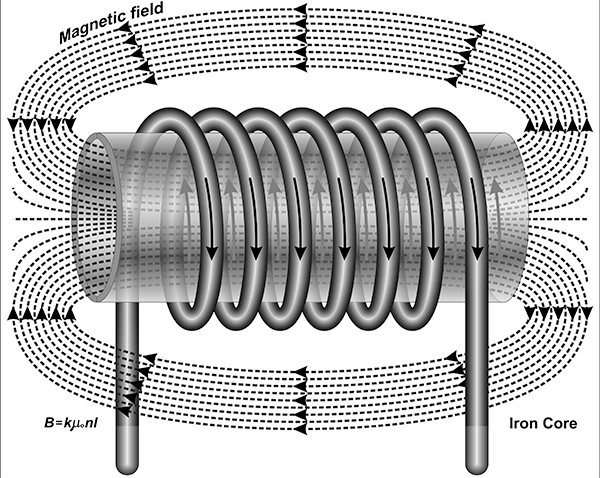

We apply fractal geometries to electromagnets to increase the magnetic flux for a given size, or, alternatively, shrink the size for a given flux. This reduction in required size allows you to put electromagnets and solenoids in places previously impossible.

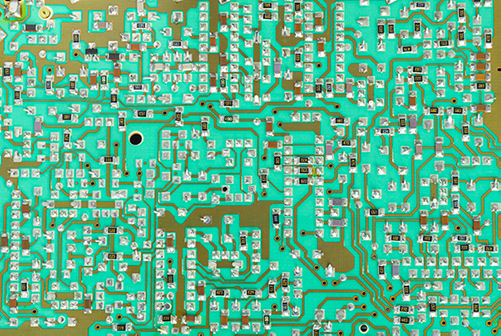

We apply fractals to the traces on printed circuit boards to reduce the likelihood of corrosion. Our technology can be applied to any trace or joints of contact with a high voltage differential to reduce the risk of corrosion. Less corrosion means higher reliability electronics and less overall cost.